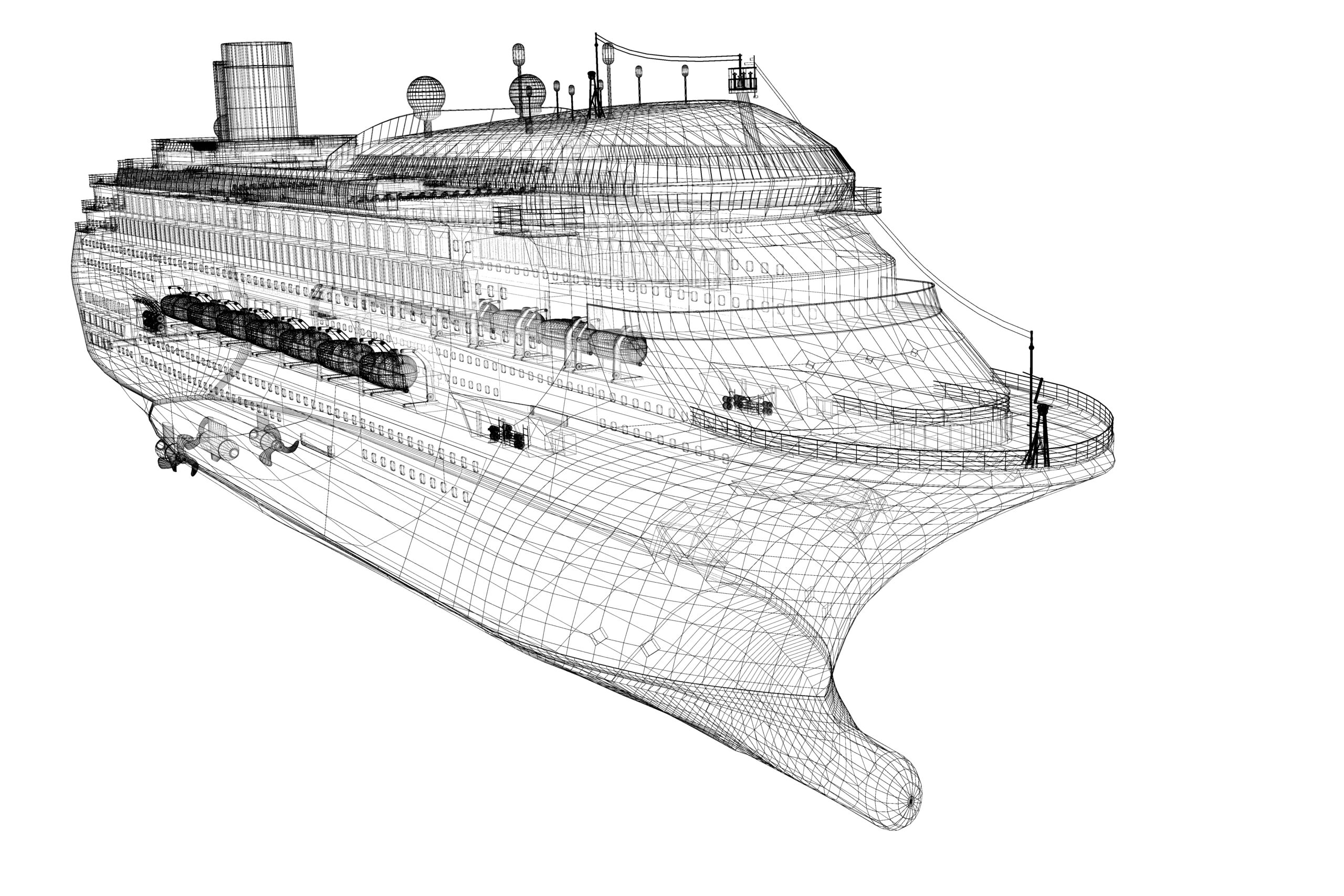

The marine industry faces significant manufacturing and maintenance challenges due to the complexity of modern vessels such as yachts, ships, submarines, and UUVs.

These challenges include the integration of advanced systems, stringent safety and environmental regulations, and the demand for custom, high-precision designs.

Maintenance is further complicated by harsh operating conditions, limited access to critical components, and the need for real-time fault detection and repair to avoid costly downtime.

Ensuring consistency, compliance, and efficiency across highly specialized production and maintenance processes requires innovative solutions and streamlined workflows.

Yacht manufacturing presents unique challenges, including complex custom designs, precise craftsmanship, the integration of advanced systems, and strict adherence to safety and environmental regulations. Managing the transition from design to production while ensuring accuracy, consistency, and timely delivery is a critical hurdle.

PROMAI’s Suite addresses these challenges by seamlessly transforming CAD designs and BOM data into executable, step-by-step manufacturing instructions. Its automated workflows and real-time monitoring ensure error-free production, while its project management capabilities streamline the coordination of tasks across teams. By optimizing processes from design to final assembly, WizSuite enhances efficiency, reduces errors, and accelerates yacht production timelines.

Shipbuilding involves highly complex workflows and extensive documentation to manage the assembly of large, intricate structures and advanced onboard systems. The main challenges include ensuring consistency across departments, maintaining accurate and up-to-date documentation, and complying with stringent international safety and regulatory standards.

PROMAI’s Suite addresses these challenges by automating the generation of precise, executable workflows directly from CAD and BOM data, creating a single source of truth for all production and maintenance processes. It ensures real-time updates, multilingual documentation, and error-free execution, enabling shipbuilders to streamline operations, improve compliance, and accelerate the production timeline while maintaining high-quality standards.

The marine industry faces significant supply chain challenges, including delays in component deliveries, fluctuating availability of specialized parts, and the need to maintain seamless production workflows. These disruptions can lead to costly downtime and missed deadlines.

PROMAI’s Shield addresses these challenges by offering real-time dynamic scheduling and task management. It intelligently reallocates tasks between available workstations without missing any steps in the production process, ensuring continuous workflow and maintaining production integrity. By enabling flexible, on-the-fly adjustments to supply chain disruptions, Shield minimizes delays, enhances efficiency, and ensures timely project completion.

Submarine and UUV (Unmanned Underwater Vehicle) manufacturing involves critical challenges, including the integration of advanced systems, extreme precision requirements, and strict adherence to safety, reliability, and environmental regulations. Managing the transition from design to production while ensuring flawless execution and maintaining operational readiness through effective maintenance is complex and resource-intensive.

PROMAI’s Suite streamlines this entire process—from design to production and maintenance—by converting CAD and BOM data into error-free, executable workflows and generating real-time, step-by-step instructions. Its proactive monitoring, automated updates, and comprehensive documentation ensure high-quality production, optimized maintenance procedures, and extended lifecycle performance for submarines and UUVs.

Certification and regulatory compliance in the marine industry are critical and highly complex, involving strict adherence to international safety, environmental, and operational standards for vessels such as ships, submarines, and UUVs.

Ensuring proper documentation, traceability, and consistent updates throughout the lifecycle of a vessel is a major challenge.

PROMAI’s Suite resolves these issues by automatically generating and maintaining up-to-date, compliant documentation directly from design and production data. Its real-time monitoring, validation, and reporting capabilities ensure that all processes meet the required regulatory standards, simplifying audits and certifications while reducing the risk of non-compliance.

Testing and Quality Assurance in the marine industry are crucial yet highly challenging due to the complexity of vessel systems, harsh operating environments, and stringent safety requirements.

Ensuring that all components, from structural elements to advanced electronics, meet performance and regulatory standards requires meticulous testing and validation.

PROMAI’s Suite resolves these challenges by automating the creation of standardized, executable testing procedures directly from design and production data. With real-time tracking, automated validation, and detailed reporting, WizSuite ensures consistency, reduces human error, and accelerates the testing process, guaranteeing high-quality, compliant marine vessels ready for deployment.

Maintenance planning in the marine industry is complex due to the vast number of critical systems onboard vessels, unpredictable operating environments, and strict safety requirements. Ensuring timely, efficient, and accurate maintenance while minimizing downtime is a significant challenge.

PROMAI’s Suite addresses these issues by providing an intelligent maintenance planning solution that leverages real-time operational data and automated workflows.

It generates proactive, step-by-step maintenance procedures, schedules preventive tasks, and ensures the availability of necessary tools and parts. With its data-driven approach, WizSuite improves maintenance efficiency, extends vessel lifespan, and enhances overall operational readiness.

Maintenance and fault isolation in the marine industry are challenging due to the complexity of vessel systems, harsh operating environments, and the critical need for rapid response to issues. Identifying faults quickly and accurately while minimizing downtime is essential for operational efficiency.

PROMAI’s Suite resolves these challenges by using real-time monitoring and advanced fault isolation techniques driven by machine learning. It provides proactive alerts, precise diagnostic insights, and guided, step-by-step repair procedures. By automating maintenance workflows and ensuring timely fault resolution, WizSuite reduces downtime, improves reliability, and ensures seamless vessel operations.

Scheduled maintenance in the marine industry is critical for ensuring vessel safety, reliability, and regulatory compliance. However, managing complex maintenance schedules across multiple systems and components can be time-consuming and prone to errors, leading to costly downtime or missed inspections.

PROMAI’s Suite simplifies and optimizes scheduled maintenance by automatically generating precise, step-by-step procedures based on real-time data and predefined intervals. Its dynamic scheduling capabilities ensure that maintenance tasks are performed on time, while providing full traceability and compliance with regulatory standards. This reduces manual effort, prevents unexpected breakdowns, and enhances the overall efficiency of marine operations.

Unscheduled maintenance in the marine industry poses significant challenges, as unexpected equipment failures can lead to costly downtime, delays, and safety risks. Diagnosing issues in complex systems like propulsion, navigation, and power requires rapid fault isolation and effective repair procedures.

PROMAI’s Suite resolves these challenges by providing real-time monitoring, event-driven alerts, and automated fault isolation using advanced data analytics. It generates step-by-step repair instructions tailored to the specific fault, ensuring quick and accurate resolution. By enabling faster response times and minimizing disruption, WizSuite helps reduce unplanned downtime and keeps vessels operational

Properly documenting, maintaining, standardizing, and ensuring compliance with regulations in manufacturing are significant challenges due to the complexity of processes, frequent design changes, and evolving industry standards. These tasks require meticulous attention to detail, real-time updates, and alignment across multiple teams and systems.

PROMAI’s Suite resolves these issues by automating the generation of standardized, multilingual, and compliant documentation directly from design data. It ensures real-time synchronization across all departments, providing up-to-date, verifiable instructions for production and maintenance. With built-in validation checks and regulatory compliance tracking,

PROMAI’s Suite helps manufacturers streamline operations, reduce errors, and consistently meet industry standards.

Maintaining yachts, ships, and submarines presents significant challenges due to the complexity of onboard systems, harsh marine environments, and the critical need for operational readiness. Ongoing maintenance requires precise fault detection, rapid fault isolation, and smart scheduling to prevent unexpected failures.

PROMAI’s Field resolves these issues by employing advanced techniques such as event-driven monitoring, machine learning-based fault isolation, and smart preventive maintenance. It continuously collects and analyzes real-time data to predict potential failures, enabling proactive maintenance and reducing downtime. By providing detailed, step-by-step repair procedures and real-time alerts, PROMAI’s Field ensures efficient, accurate, and cost-effective maintenance across marine operations.

Testing and inspection before the delivery of ships and submarines are critical yet highly challenging processes in the marine industry. These vessels require comprehensive verification of complex systems, including propulsion, electronics, and safety equipment, to ensure they meet rigorous performance and regulatory standards. The manual nature of these procedures often leads to delays, inconsistencies, and increased costs.

PROMAI’s Suite resolves these issues by automating the generation of standardized test and inspection procedures directly from design data, ensuring consistency and accuracy. With real-time monitoring, automated validation, and detailed reporting capabilities,

PROMAI’s Suite streamlines the inspection process, reduces human error, and accelerates delivery timelines while ensuring compliance with industry regulations.

Shipbuilding involves significant challenges due to the sheer scale of projects, complex designs, the need for precision in assembly, and strict regulatory compliance. Managing thousands of components, coordinating across multiple teams, and ensuring error-free execution are critical hurdles.

PROMAI’s Suite addresses these challenges by automating the transformation of CAD and BOM data into standardized, executable manufacturing processes. It enables real-time task management, error detection, and dynamic scheduling to optimize workflows. Additionally, PROMAI ensures seamless documentation and compliance, improving efficiency, reducing rework, and accelerating project completion while maintaining the highest quality standards.

visibility_offDisable flashes

titleMark headings

settingsBackground Color

zoom_outZoom out

zoom_inZoom in

remove_circle_outlineDecrease font

add_circle_outlineIncrease font

spellcheckReadable font

brightness_highBright contrast

brightness_lowDark contrast

format_underlinedUnderline links

font_downloadMark links