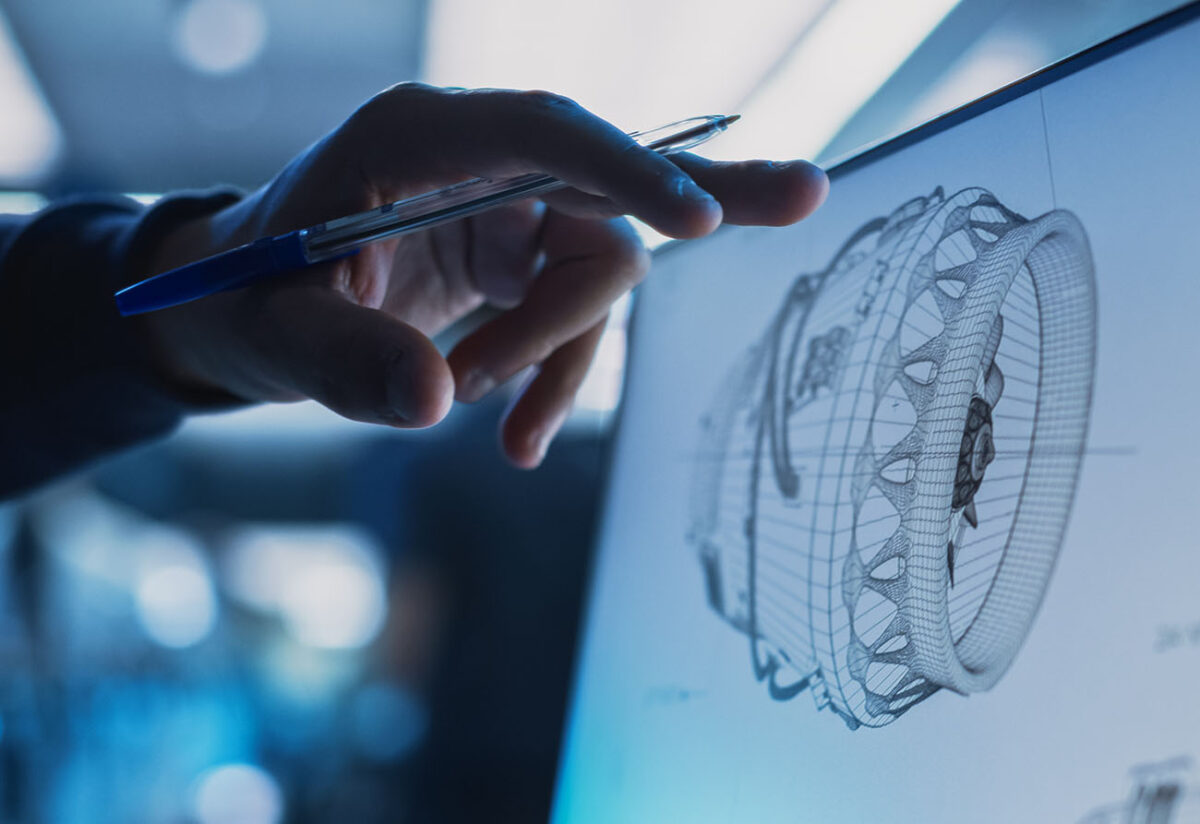

Aviation production is among the most complex industries, requiring absolute precision, compliance with strict regulations, and seamless coordination of intricate processes. Challenges such as managing global supply chains, minimizing human error, and ensuring consistent quality across components make efficient production a significant hurdle.

WizSuite tackles aviation challenges with precision, providing standardized, executable solutions that streamline complex production and ensure compliance

Aviation manufacturing operates under stringent regulatory requirements, demanding flawless adherence to safety and quality standards across every component and process. Non-compliance can result in costly delays, rework, or grounding of aircraft.

WizSuite addresses this challenge by generating standardized, compliant, and auditable documentation tailored to meet industry certifications. Its automated tools ensure accuracy and consistency, simplifying compliance processes and minimizing the risk of regulatory issues.

Managing global supply chains in aviation is a complex challenge, involving multiple suppliers, dynamic logistics, and the need for real-time adaptability. Delays, disruptions, and miscommunications can significantly impact production timelines and costs

WizShield overcomes these hurdles with its dynamic scheduler, which adjusts production timelines in real time based on material availability. Its smart task differ algorithms instantly detect and flag task or component changes, while proactive optimization algorithms forecast potential disruptions and recommend actionable solutions, such as alternate sourcing or task resequencing. Together, these tools ensure seamless supply chain integration, reducing delays and enhancing efficiency.

Human error is a critical challenge in aviation production, where even minor mistakes can lead to costly reworks or safety risks.

WizShield resolves this issue with its executable, step-by-step atomic instructions, guiding operators through precise tasks with clear, detailed directions. Each step includes verifiable results, ensuring that every action is completed accurately before moving to the next. This structured approach minimizes ambiguity, reduces errors, and ensures consistent quality across all production and maintenance processes.

Coordinating complex aviation processes, involving multiple tasks, teams, and systems, is a significant challenge that can lead to inefficiencies and delays.

WizShield addresses this with its dynamic scheduler and AI-triggered event-driven algorithms, which adapt workflows in real time to changing conditions. These tools integrate with executable step-by-step atomic instructions, ensuring that each task is performed sequentially and correctly. With verifiable results per step, teams can confirm accuracy at every stage, enabling seamless coordination and reducing the risk of missteps in even the most intricate processes.

Before an aircraft can be delivered to the customer, it must undergo a certification process.

This involves comprehensive testing to meet the airworthiness requirements established by aviation regulatory authorities, such as the Federal Aviation Administration (FAA) in the United States.

The aircraft must demonstrate full compliance with safety, performance, and operational standards.

WizGen streamlines this process by automating the creation of checklists for all required regulatory tests, while WizShield ensures that each test is conducted accurately and in alignment with these requirements.

At various stages of production, stringent testing and quality assurance measures are implemented to ensure the safety and reliability of the aircraft.

In aviation production, specialized tests such as fatigue testing and environmental simulations (e.g., high-pressure altitude testing) are also conducted to ensure the aircraft’s durability and performance under extreme conditions.

Any issues or defects identified during testing are promptly addressed and rectified to maintain the highest standards of safety, compliance, and quality.

Airlines and aircraft operators develop maintenance plans based on regulatory requirements, manufacturer recommendations, and their own maintenance programs.

These plans outline scheduled maintenance tasks, including routine inspections, preventive maintenance, and component replacements.

PROMAI’s WizGen automates the creation of maintenance, fault isolation procedures that are complete and validated.

Maintenance and fault isolation are critical aspects of aviation to ensure the safe and reliable operation of aircraft.

Maintenance involves the routine inspection, servicing, repair, and replacement of components to keep the aircraft in airworthy condition.

Fault isolation, on the other hand, is the process of identifying and troubleshooting issues or faults in the aircraft’s systems or components.

Here’s an overview of maintenance and fault isolation in aviation

Scheduled maintenance involves routine inspections and servicing at specified intervals. This includes checks of systems, structures, engines, and other components to ensure they are functioning properly and within acceptable limits.

Regular maintenance tasks may include lubrication, filter replacement, fluid checks, and system functional tests.

Integrating WizShield tracks the different steps and alerts for any maintenance procedure that should be performed, Using WizOpt will maximize operation time of each aircraft component.

Unscheduled maintenance occurs when an aircraft experiences an unexpected issue or failure.

This could be due to a system malfunction, component failure, or any other unforeseen event.

Aircraft maintenance technicians (AMTs) assess the problem, troubleshoot, and perform necessary repairs to restore the aircraft to airworthy condition.

PROMAI’s WizSuite generates complete fault isolation procedures that will assists momentarily isolating the issue or failure save time and time on the ground of the entire fleet.

visibility_offDisable flashes

titleMark headings

settingsBackground Color

zoom_outZoom out

zoom_inZoom in

remove_circle_outlineDecrease font

add_circle_outlineIncrease font

spellcheckReadable font

brightness_highBright contrast

brightness_lowDark contrast

format_underlinedUnderline links

font_downloadMark links