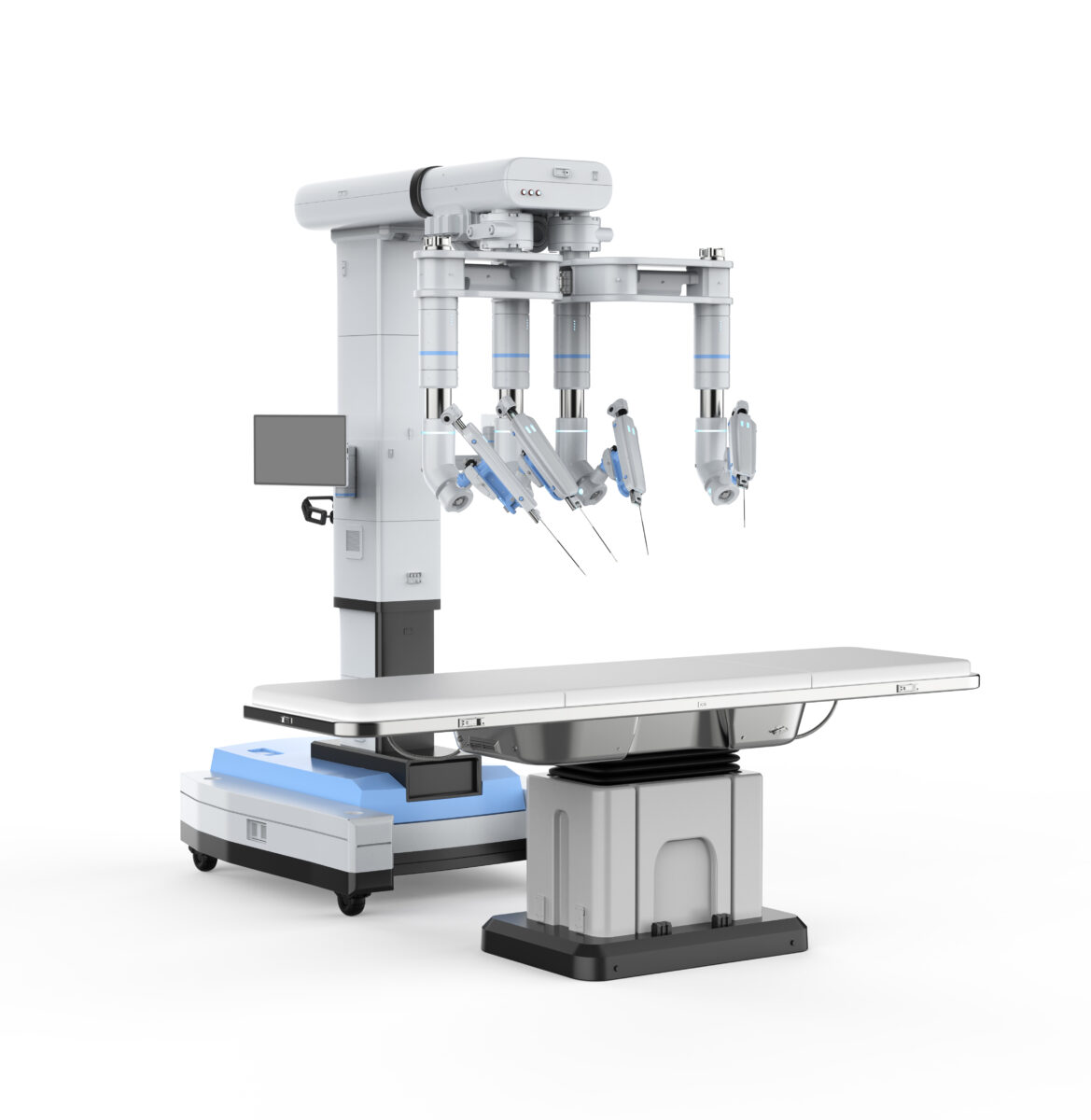

Moving from prototyping to full-scale fabrication of medical devices presents significant challenges, including optimizing production line setups, dynamically scheduling tasks to meet key performance indicators (KPIs), ensuring consistent process execution, and minimizing downtime through effective fault isolation and preventive maintenance.

PROMAI’s Suite streamlines this transition by offering optimized production line planning and real-time, dynamic task scheduling to maximize efficiency. The Suite generates verifiable, multilingual step-by-step processes, ensuring clear communication across global teams.

Additionally, its advanced fault isolation and preventive maintenance features help reduce errors and equipment failures, enabling high-quality, consistent, and scalable manufacturing.