Understanding industrial efficiency

Improving industrial efficiency means making factories and processes more productive and less wasteful. This can involve using new technology and methods to save time, energy, and resources. Companies aim to produce more goods with less effort and cost. Factors like automation, data analysis, and sustainable practices play a key role in achieving this goal.

Importance of efficiency in manufacturing

Efficiency is crucial in manufacturing because it helps companies reduce waste, save time, and increase productivity. By streamlining processes and utilizing advanced technologies, manufacturers can produce goods faster and at a lower cost. Improved efficiency also allows companies to stay competitive in the ever-evolving market by meeting consumer demands efficiently and delivering products on time.

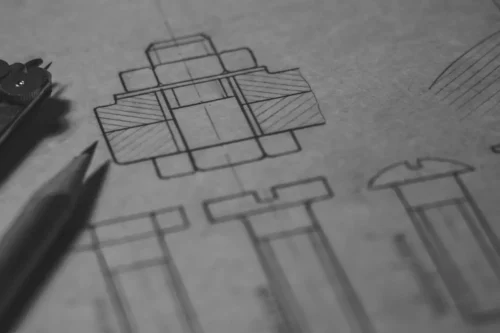

How advanced manufacturing technologies can reduce reworks

Advanced manufacturing technologies can help reduce reworks by improving precision and efficiency in the production process. These technologies can identify errors early on, allowing for quick adjustments to be made before products are completed. Additionally, automated systems can streamline production workflows, minimizing human errors that often lead to reworks. By integrating advanced manufacturing technologies into operations, companies can enhance productivity while decreasing the need for costly rework processes.

Role of technology in improving efficiency

Industrial efficiency has been greatly enhanced by technology advancements. With the use of automation and data analytics, manufacturers can streamline their processes, reduce errors, and increase productivity. Smart factories equipped with sensors and connected devices allow for real-time monitoring and control of operations, leading to quicker decision-making and optimization. Machine learning algorithms are also employed to predict maintenance needs, reducing downtime and increasing overall equipment effectiveness. These technological innovations are revolutionizing the manufacturing landscape, paving the way for a more efficient and competitive industry.

Trends shaping the future of manufacturing technology

Companies are increasingly investing in automation technology to improve efficiency and productivity in manufacturing processes. Robotics and artificial intelligence play a significant role in shaping the future of manufacturing technology.

3D printing is revolutionizing the industry by allowing for rapid prototyping and customization of products.

Internet of Things (IoT) devices are being integrated into manufacturing equipment to enable real-time monitoring and data analysis. This helps in predictive maintenance and optimizing production processes.

Innovations driving industrial efficiency

Innovations in the manufacturing industry are leading to increased efficiency. By integrating technologies like artificial intelligence and automation, businesses can streamline their production processes, minimize human error, and optimize resource utilization. Some key innovations that are driving industrial efficiency include:

- Predictive Maintenance: Using sensors and data analytics to anticipate equipment failures before they happen, reducing downtime and maintenance costs.

- Internet of Things (IoT): Connecting machines and devices to enable real-time monitoring and control, facilitating better decision-making and improving overall efficiency.

- Additive Manufacturing: Utilizing 3D printing technology to produce complex parts in a more cost-effective and time-efficient manner.

- Smart Factories: Implementing interconnected systems and intelligent automation to create flexible and responsive manufacturing environments.

These innovations not only enhance productivity but also pave the way for a more sustainable and competitive future in the manufacturing sector.

Automation and robotics in manufacturing

Manufacturing industries are adopting automation and robotics to increase production efficiency. Robots can perform tasks like welding, painting, and assembling products with high precision and speed. Automation reduces the need for human labor, leading to faster turnaround times and lower error rates in manufacturing processes. With advancements in technology, companies are investing in robotics to stay competitive in the market.

Sustainable practices for enhanced efficiency

Sustainable practices are becoming crucial for businesses aiming to boost efficiency while minimizing their environmental impact. Implementing practices such as energy-efficient machinery, waste reduction initiatives, and recycling programs not only improve operational efficiency but also contribute to a greener, more sustainable future. By prioritizing sustainability in manufacturing processes, companies can streamline operations, reduce costs, and position themselves as industry leaders in innovation and environmental responsibility.

Conclusion: Embracing the future of manufacturing tech

To thrive in the ever-evolving world of manufacturing, embracing the latest technological innovations is crucial. Companies that integrate advanced technologies like robotics and automation into their processes not only boost their efficiency but also stay ahead of the competition. Investing in smart factories and IoT devices enables real-time monitoring and analysis, leading to faster decision-making and better control over operations. By embracing these cutting-edge solutions, manufacturers can streamline production, reduce costs, and improve overall productivity.