Introduction to Data Analysis in Manufacturing

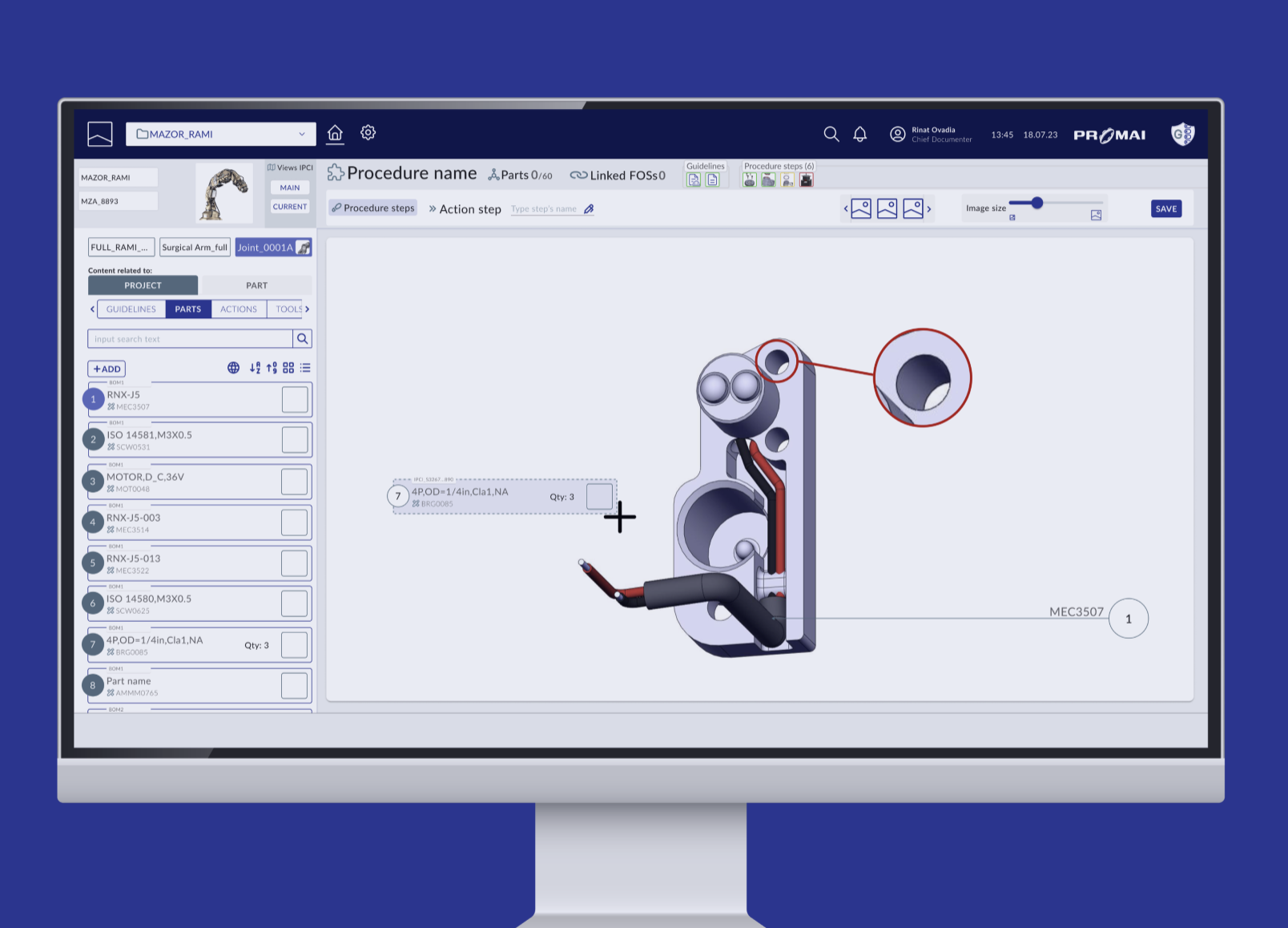

Data analysis is revolutionizing the manufacturing process, paving the way for more efficient production and higher quality products. By analyzing data, manufacturers can identify patterns, trends, and anomalies that help them make informed decisions and optimize their operations. This blog will explore how data analysis is being used in manufacturing to streamline processes, improve product quality, and drive innovation in the industry.

Importance of Data Analysis in the Manufacturing Process

Data analysis plays a crucial role in modern manufacturing. It helps companies make informed decisions based on real-time information, leading to improved efficiency and productivity. By analyzing data, manufacturers can identify trends, predict equipment failures before they occur, and optimize processes to reduce downtime. This results in cost savings and a competitive edge in the industry.

Data analysis in manufacturing helps identify inefficiencies in the production process, leading to improvements that streamline operations. By analyzing data, manufacturers can pinpoint areas for enhancement, such as reducing downtime, optimizing inventory levels, and enhancing equipment maintenance schedules. This proactive approach enables companies to make data-driven decisions, resulting in increased productivity and cost savings.

Enhancing Quality Control with Data Analysis

Data analysis is revolutionizing the manufacturing process by improving quality control. By utilizing data analysis techniques, manufacturers can identify defects and inefficiencies earlier in the production cycle. This allows for adjustments to be made swiftly, leading to higher-quality products and increased efficiency. With data analysis, manufacturers can make informed decisions based on real-time information, ensuring that each product meets quality standards before reaching consumers.

Predictive maintenance through data analysis helps companies prevent machinery breakdowns by analyzing data to predict when maintenance is needed. This proactive approach reduces downtime and saves money by fixing issues before they become critical. Data analysis provides insights into the condition of equipment, allowing for timely repairs and reducing unexpected failures. This process transforms the manufacturing sector by streamlining operations and optimizing efficiency.

Supply Chain Optimization Using Data Analysis

Data analysis plays a crucial role in optimizing supply chains. By leveraging data insights, companies can streamline their operations, reduce costs, and enhance efficiency. Here’s how data analysis transforms the supply chain:

- Increased Visibility: Data analysis provides real-time visibility into inventory levels, shipment statuses, and production schedules, allowing companies to make informed decisions quickly.

- Predictive Analytics: By analyzing historical data, companies can predict demand patterns, identify potential risks, and optimize inventory levels to meet customer needs efficiently.

- Enhanced Collaboration: Data analysis fosters collaboration among different stakeholders in the supply chain, ensuring smoother communication and coordination for better overall performance.

- Cost Savings: Through data analysis, companies can identify areas for cost savings, such as reducing transportation costs, minimizing waste, and improving resource utilization.

By harnessing the power of data analysis, companies can achieve supply chain optimization, improving their competitiveness and responsiveness in today’s dynamic market environment.

Overcoming Challenges in Adopting Data Analysis in Manufacturing

Adopting data analysis in manufacturing may face challenges. These challenges include integrating new technologies with existing systems, ensuring data accuracy and security, and training employees to utilize data effectively. To overcome these obstacles, companies must invest in robust training programs, prioritize data integrity, and gradually implement data analysis tools to ensure a smooth transition.

Data analysis is revolutionizing the manufacturing industry by improving efficiency and productivity. With real-time data monitoring, manufacturers can identify issues faster and make immediate improvements. Predictive maintenance helps prevent equipment breakdowns, reducing costly downtime. Quality control is enhanced through data analysis, ensuring higher product standards. Overall, data analysis is shaping the future of manufacturing, making processes more streamlined and effective.